- Product Description

5-axis additive and subtractive laser 3D printer

ProAM-605LDM

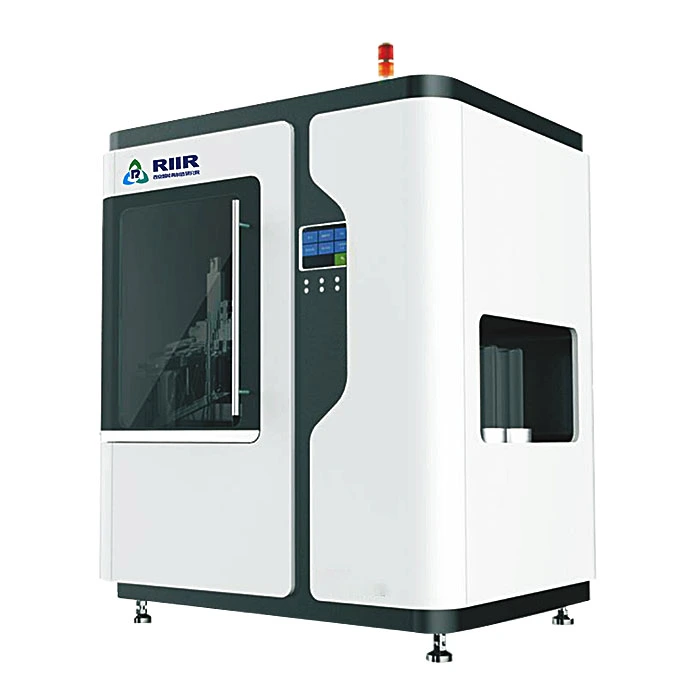

1. product picture

2. product use

The ProAM-605LDM-5-axis additive-multiplicative integrated laser 3D printer is designed for rapid prototyping of shaft, flat, and curved components in defense, aerospace, and rail transit sectors, as well as emergency repairs.

l Additive Surface Part

l Additive Manufacturing of Flat Parts

l Additive manufacturing for shaft components

3. How it works

The ProAM-605LDM-5-axis additive-multiplicative integrated laser 3D printer employs composite additive manufacturing technology centered on Directed Energy Deposition (DED). This innovative process utilizes laser beams or other energy sources to melt metal wires or powders, enabling layer-by-layer deposition on substrates for structural reinforcement or 3D part fabrication. The system supports simultaneous additive and multiplicative manufacturing, representing an advanced DED technology that combines multiple processes and material types.

l Process composite: laser and other forms of energy composite to improve efficiency and quality.

l Material composite: Different types of material composite additive can improve the surface properties of parts.

▲ metal dust ▲

4. Product Advantages

l Additive and subtractive integration: Featuring modular design with subtractive machining tool library, additive manufacturing (AM) offline programming software, component model library, and AM processing technology, it enables integrated additive and subtractive processing for complex part printing and repair.

l Low thermal input: The low thermal input further reduces the deformation of the laser cladding process, which can be used for remanufacturing or new production of shaft, plane and curved parts

l Versatile material compatibility: Suitable for cladding processing of various materials including stainless steel, copper alloys, nickel-based alloys, cobalt-based alloys, and titanium alloys.

l Easy to operate: Highly automated with built-in parameter algorithms and process packages, one-click invocation

5. Device Parameters

order number | unit type | parameter |

1 | Forming dimensions (mm) | 600*400*300(W x D x H) |

2 | Additive manufacturing method | LENS laser near-net-shape forming technology |

3 | Subtractive manufacturing method | AC CMM (CMM) Five-axis machining center (X, Y, Z, A, C) |

4 | Additive laser power (W) | 6000 |

5 | lift height | 0.1mm~2.0mm Continuous adjustment |

6 | Print Precision | 0.1mm |

7 | print out rate | 500-2000g/h |

8 | molding material | Various carbon steel, stainless steel, nickel-based, cobalt-based alloys, and aluminum alloy materials |

9 | Spindle cutting speed (r/min) | 12000 |

10 | Cut thickness (mm) | 0-100 Adjust according to material and thickness |

11 | Workbench load (kg) | 500 |

12 | navar | Self-developed ProAM 3D printing control system |

13 | Supplementary software | Self-developed ProLC automatic programming software |

14 | Total equipment weight (T) | ≈6 |

15 | Device transportation method | Forklift & truck handling |

16 | Device size (mm) | Approximately 2550*2400*2750 |